Description

Saylor-Beall Rotary Screw Compressors RSD 40-50 U

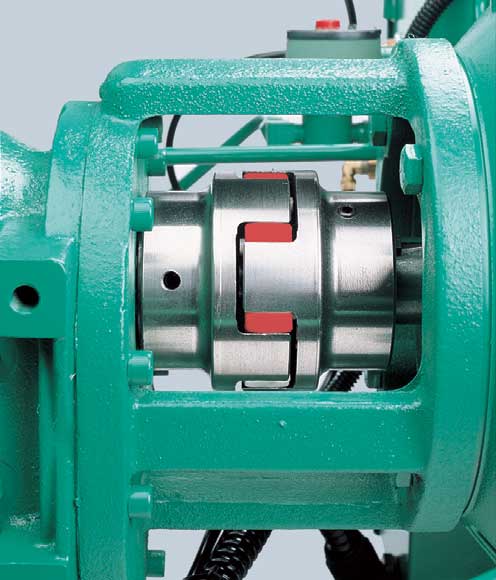

The advantage of owning a Saylor-Beall rotary screw air compressor is that it has one of the most reliable, high performance, low maintenance air ends in the industry. Our advanced rotor design features oversize radial thrust bearings and precision working rotors that provide virtually no wear. With less friction and less heat, the compressor runs cooler and the circulating fluid lasts longer. We offer protective devices such as a Class 20 solid state overload relay, high temperature and over pressure shut-down switches, and an anti-restart pressure switch that prevents starting while the air compressor is pressurized.

Saylor-Beall Manufacturing Co, in co-operation with our sister company Sulivan/Palatek is pleased to offer rotary screw compressors ranging from 10 to 50 H.P. Our rotary screw compressors are manufactured in a state of the art facility in Michigan City, IN.

Advantages of Having a Saylor-Beall in combination with Sullivan-Palatek Rotary Screw Compressor

Sullivan-Palatek manufactures one of the most reliable, high performance, low maintenance air ends in the industry. Advanced rotor design features oversized radial thrust bearings and precision working rotary screws that provide virtually no wear. With less friction and less heat, compressors run cool and the circulating fluid lasts longer.

Engineered to be both reliable and versatile, the RSM-Series industrial air compressor is another energy efficient continuous duty compressed air solution. These units are equipped with full voltage magnetic starters, automatic dual control, and easily replaceable combination pleated and foam dry type air filters. Compact in size, they are ideally made to be used in smaller industrial settings such as automotive shops, small machining factories and textile workshops.

- T1 Microprocessor – Program daily schedule to suit plant requirements

- Electric Motor – 460/3/60 standard (230/3/60 optional on most models)

- Motor Starter – Full voltage magnetic starter with 115 volt controls, NEMA 1, NEMA 4, Wye Delta, VFD – Optional

- Protective Devices – Class 20 Solid State overload relay, anti reverse, high temperature and high pressure shutdown

- Lube Fill & Level Elbow – One piece fluid fill elbow and level indication sight glass

- Separator Tank – ASME coded 200PSIG tank, relief valve, minimum pressure/ check valve

- Cooling System – Cooling system with dedicated fan motor, large side by side oil cooler and aftercooler

- Air Intake Filter – Heavy duty dry type with easily replaceable elements

- Inlet/check valve – One piece housing for dependable performance and complete modulation

- Coupling & Drive – Compressor is flange mounted to motor C-face for positive alignment and direct driven

- Controls – 0-100% modulation, solenoid controlled for smooth lowest possible no load power

Updraft design allows hot air to be recovered or exhausted thru top of the machine

Dedicated fan motor and side by side oil cooler and air cooled aftercooler for easy cleaning